THE PROJECT

Located within the Donaldson Coal Mine lease is the Chichester Trunk Gravity Main (CTGM). Built in the 1960s, the CTGM comprises a 914 mm (36”) diameter mild steel welded pipe with cement lining. It is situated above ground supported on concrete saddles at approximately 7.6 m centres, and thrust and restraining blocks at 45 to 75 m intervals.

PSM was engaged to investigate the effect on the CTGM on open-pit blasting carried out by the Donaldson Coal Mine to fragment overburden before excavation. The aim of the PSM investigation was to provide a rational basis to control blasting near the pipeline.

ENGINEERING AND TECHNICAL CHALLENGES

A high-value asset owned by the Hunter Water Corporation (NSW), the CTGM is a critical public water supply pipeline from the Chichester Dam, supplying the Stony Pinch Reservoir and, in turn, the regional city of Newcastle. Loss of operation for periods greater than 24 hours can result in loss of service.

Donaldson wished to maximise mine productivity by blasting close to the CTGM while maintaining peak particle velocities (PPV) less than specified limits. The interaction between ground and pipeline deformation in response to blasting required specialised advice encompassing expertise in blasting, ground conditions, engineered materials and pipeline construction.

APPROACH AND INNOVATION

Following a rigorous assessment and modelling, PSM’s tailored approach included:

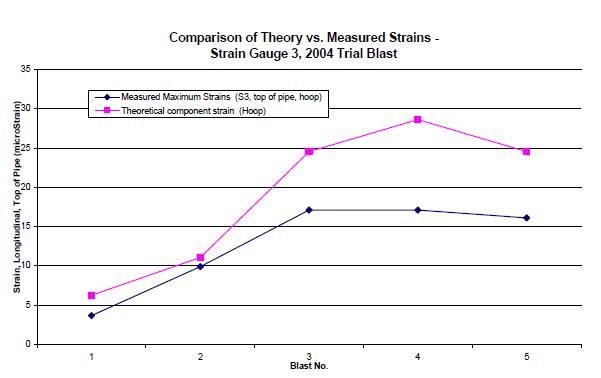

- Field monitoring of particle velocities on the pipe due to blasting

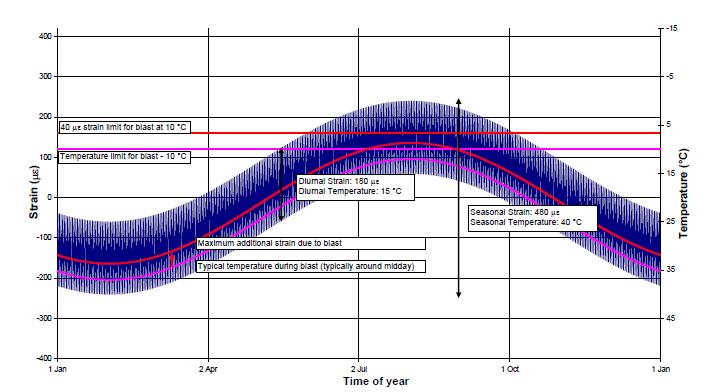

- Preparation of theoretical calculations and field monitoring of pipe strain due to blasting and operational conditions

- Preparation of theoretical calculations of pipe stress, cement lining crack width, and ground tilt due to blast-induced strains

- Identification of the induced strains in the structural steel pipe and the internal cement lining in response to temperature and blasting

- Development of a theoretical basis to assess induced strains, corresponding stresses and ground tilt in response to blasting and/or temperature effects

- Prediction of pipeline response to differing blast offset distances and detonation size and sequencing

- Comparison of prediction results against measured results to the specified limits.

OUTCOMES

PSM successfully reconciled the competing objectives of maximising blasting productivity with protecting public asset integrity to an agreed standard. The study concluded that blasting can be controlled to generate stresses and strains that are below those likely to have been experienced during operations to date. PSM also recommended modification of existing controls on both peak particle velocity and strain.

Services: #Blasting operations #Coal mine #Open pit #Pipeline #Water supply